Description

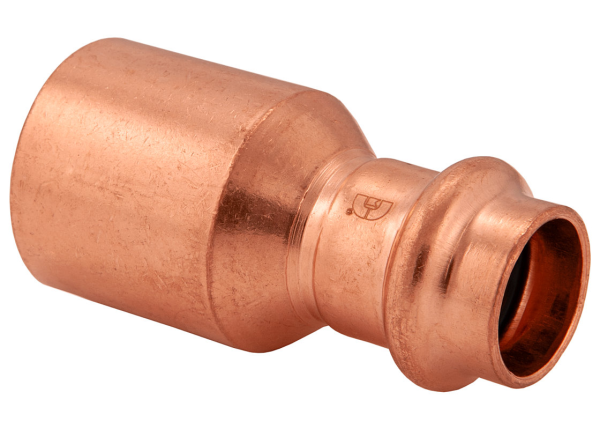

BMI 2" x 1/2" Wrot Copper Press-Fit FTG x P Bushing Fitting Item 47144 .

Features & Benefits:

- 50 Year Limited Warranty against defect in material and workmanship

- Compatible with all major brands pressing tools

- 360 Degree Leak Detection Design

- Lead-Free

- UPC / CUPC

- IAPMO PS 117-2016

Applications:

- Potable Water

- Hydronic Heating (w/Glycol)

- Chilled Water

- Compressed Air (200 psi max.)

- Non-Medical Gases (140 psi maximum)

- Low Pressure Steam (15 psi maximum)

Available Sizes:

- 3/4" x 1/2" (47123), 1" x 3/4" (47127), 1" x 1/2" (47128), 1-1/4" x 1" (47131), 1-1/4" x 3/4" (47132), 1-1/4" x 1/2" (47133), 1-1/2" x 1-1/4" (47135), 1-1/2" x 1" (47136), 1-1/2" x 3/4" (47137), 2" x 1-1/2" (47140), 2" x 1-1/4" (47141), 2" x 1" (47142), 2-1/2" x 2" (47146), 2-1/2" x 1-1/2" (47147), 2-1/2" x 1-1/4" (47148), 2-1/2" x 1" (47149), 3" x 2-1/2" (47151), 3" x 2" (47152), 3" x 1-/12" (47153), 3" x 1-1/4" (47154), 4" x 3" (47157), 4" x 2-1/2" (47157), 4" x 2" (47158)

Application References:

- All tubing used must be as per ASME/ASTM B88 standard K, L and M hard copper tubing from ½" to 4" and soft copper tubing in ½" to 1¼" diameters.

Leak Detection:

- BMI Press fittings are made with a Leak Detection Design, providing fast and easy identification of unpressed connections during the pressure testing process in any installation angle possible.

- The design feature provides a path for liquids and/or gases from inside the system past the sealing element of an unpressed connection.

- When pressed according to instructions, the Leak Detection Design feature is neutralized, creating a leak proof, permanent connection.

- Unpressed connections are located by pressurizing the system with air or water. When testing with water the suggested pressure of 15 to 85 psi maximum. (Test with air can be dangerous, manufacturer recommend testing compressed air at ½ to 45 psi maximum.

- Following a successful test, the system may be pressure tested up to 600 psi maximum for water and 200 psi maximum for air, depending on local code requirements.

Operating Information:

- Working pressure: 200 psi Max.

- Max test pressure: 600 psi Max.

- Low pressure steam: 15 psi Max.

- Working temperature: 0~250 F (-18~121 C)

- Vacuum: 29.2" Mercury @ 68 F (20 C)

Compliance:

- Materials: ASME/ASTM B42 C12200 (99.9% cu)

- Dimensions: IAPMO PS 117-2016

- Threads: ASME/ASTM B1.20.1

- Drinking water: NSF/ANSI STANDARD 61 - 372 (Lead free)

- Other: ISO9001, ISO14001

Technical Downloads:

- BMI Wrot Copper Press-Fit Fitting: Specification Submital

- BMI Wrot Copper Press-Fit Fitting: Installation Instructions

- BMI Wrot Copper Press-Fit Fitting: Promotional Flyer

Estimate shipping

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.